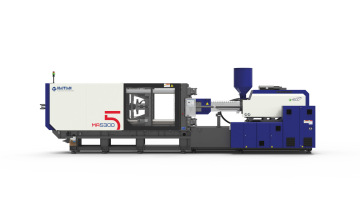

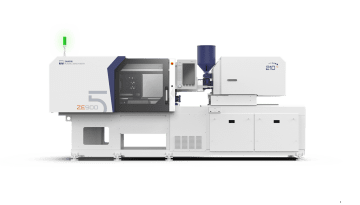

ZERES V

The Zeres Series bridges the gap from electric injection technology to the traditional applications known in hydraulic machinery. It has an identical design to the Venus Series. Main movements such as mould closing/opening, injection and plasticizing are controlled by electric drives. The movements of the injection unit, ejector and core control are carried out by a servo-hydraulic system. In this way, Zeres Series injection moulding machines not only provide the user with a wide range of applications, but even greater production efficiency. Today, Zeres injection moulding machines are available in sizes ranging from 400 kN to 13,800 kN of clamping force.

Electric - hybrid

400 - 13 800 kN

Integrated hydraulic system

Intelligent motion control for short dry cycle times

Main benefits

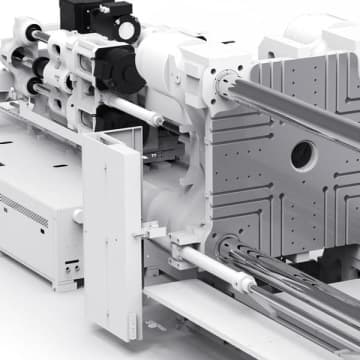

Precision and repeatability

Linear guides provide reduced friction coefficient during mould movements, clean working space, accurate position control and repeatability.

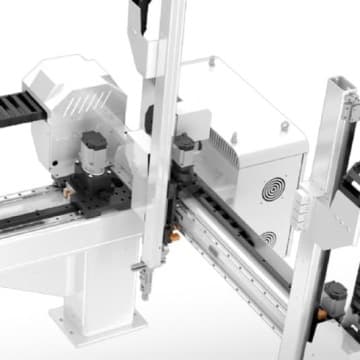

MOTION PLUS mould protection

Intelligent algorithms provide highly reactive and precise mould protection

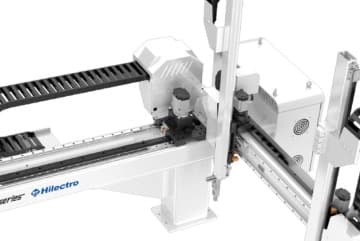

Open integration - Connectivity Plus

Open integration capability with all popular industrial automation interfaces and peripherals

Standard technical specification of the ZERES series

- 5-point twin toggle mechanism

- Center pressing platen

- Clamping force settable at control panel

- Automatic mold-height adjustment

- Platen moving speed 6 steps

- Full stroke mold protection

- Clamping force pre-release

- Ejector speed 3 steps

- Ejector pressure 3 steps

- Multi ejection function

- Ejection parallel to mold opening

- Abrasion-resistant screw set, general version

- Open nozzle

- Barrel heating PID control, SSR

- Extended nozzle, temperature PID control independently

- Feeding zone temperature closed-loop control

- Injection speed 6 steps

- Speed responding mode adjustable

- Holding pressure 4 steps

- Pressure responding mode adjustable

- V/P switch over methods by position/ time/ pressure combinations

- Dosing rotation speed 3 steps

- Back pressure 3 steps

- HPM over-filling protection function

- Screw retraction before and/or after dosing

- Auto purge

- Nozzle sealing force programmable control

- Swiveling injection unit

- Multi-language available (Chinese, German, English, Japanese etc.)

- Metric/Imperial unit selectable

- Dosing parallel to mold opening

- Injection compression

- Production assistant device function

- Maintenance alert

- 5000 cycles process data recording

- Amendment report

- Alarm record

- Quality control function

- Mold profile data memory (up to 200 sets)

- 3 USB interface

- USB printer interface

- Injection speed & pressure curve

- 1 free programmable I/O

- Mold ejector protection interface

- EUROMAP 12 interface for handling device

- Auxiliary socket 3PH/380V 32A×1, 16A×2

- 3 color alarm lamp (red/yellow/green)