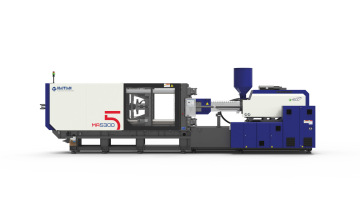

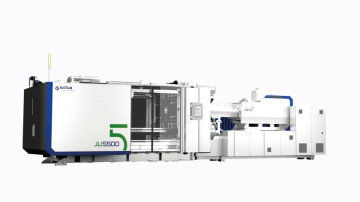

JUPITER V

Developed based on research and development experience in two-platen technology over the past two decades, the Haitian Jupiter V Series offers significant improvements over the previous generation of machines and a number of advantages for a wide range of injection molding applications. The enhancements include additional features and user applications that significantly improve machine performance and part quality. With flexible combinations of the clamping unit with the injection unit, the machine can be adapted to specific injection molding applications.

Two-platen hydraulic with servo drive

4500 - 55 000 kN

Energy-saving servo technology

Compact design

Main benefits

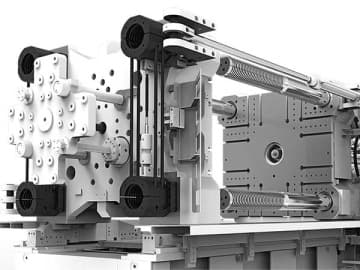

Space-saving two-platen design

Extended opening stroke and ejector stroke for diverse applications and more space for mold assembly.

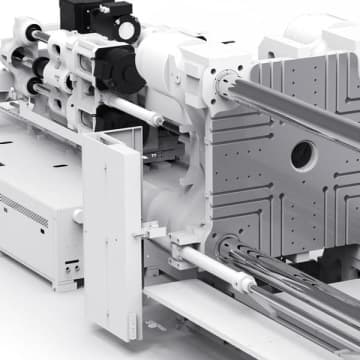

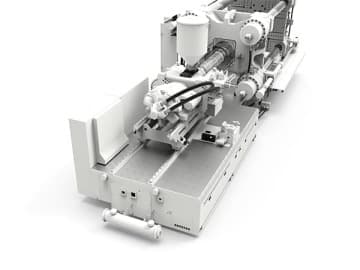

New injection unit

Linear guides for reduced friction and energy consumption and improved precision. The free choice between linear and staged injection function, provides greater process efficiency and expands the range of applications.

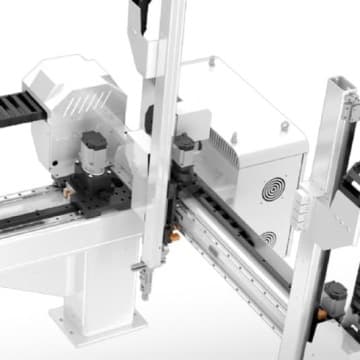

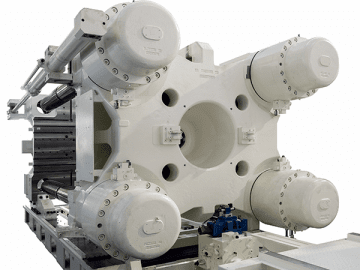

Quick and precise closing system

Four short-stroke clamping cylinders on the fixed platen enable fast and precise adjustment of the mold clamping force. Real-time monitoring with pressure sensors results in high repeatability of the clamping force.

Standard technical specification of the JUPITER series

- Fixed plate four cylinder straight locking moving plate clasp two plate type mold closing unit

- High rigidity moving plate supports sliding foot

- Diagonal slanting type rapid mold open/close mechanism

- High rigidity, high strength Haitian patent mold platen

- Synchronous locking mechanism

- Inverted double cylinder ejector mechanism (JU III 12000kN – JU III 55000kN)

- Mechanical coupling for easier ejector connection

- Haitian standard T-slot + threaded hole mold platen

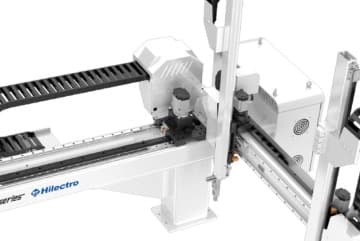

- The hole installion for robot (EU 18)

- Embedded positioning ring (fixed plate)

- 5-stage mold open/close,pressure & speed adjustable

- Independent/linkage switching function of mold opening and ejector system (JU III 7500kN – JU III 55000kN)

- Automatic mold height adjustment function for clamp force setting

- Electrical and hydraulic double interlcok security

- Ejector back stroke adjustable function

- Three hydraulic ejector modes (vibration, maintenance, multiple times)

- Delay ejector out and ejector back function

- Program controllable of ejector(2 paragraphs)

- Mould clamping oil pressure sensor detection function

- Multi-stage proportional control of clamping force

- Mould clamping force pressure safe pressure limiting function

- Safety and pressure limiting function of mold breaking pressure

- Low clamping force holding function in the mode of mold adjustment when turn off the motor

- The clamping force can be decompressed automatically when the machine is off in manual and automatic mode

- Spring mould fuction

- Mould area safety pedal (JU III 9000kN – JU III 55000kN)

- Fast mold opening device

- Low pressure mold protection function

- Two unit transformations of clamping force (TON and Bar)

- Twin cylinder balanced injection system

- Twin cylinder injection unit hydr. Control

- Injection safety cover

- Nozzle safety cover

- Barrel heating safety cover

- Injection unit anti-slip Aluminum cover (JU III 4500kN – JU III 14000kN)

- Injection unit anti-slip steel cover (JU III 16000kN – JU III 55000kN)

- Nozzle centering alignment device

- Injection unit swiveling device

- Linear guide of injection and injection unit

- Steel hopper(50kg) (JU III 4500kN – JU III 5500kN),

- Steel hopper(100kg) (JU III 6500kN – JU III 10800kN)

- Hopper dryer and auto loader(SHINI 200kg) (JU III 12000kN)

- Hopper dryer and auto loader(SHINI 400kg) (JU III 13000kN – JU III 33000kN)

- Hopper dryer and auto loader(SHINI 600kg) (JU III 40000kN – JU III 55000kN)

- High torque motor for screw plasticization

- Screw speed sensor

- Additional extended nozzle (JU III 4500kN – JU III 21000kN)

- With Mixing ring to increased color mixing (JU III 5500kN B/C/D, JU III 6500kN – JU III 55000kN)

- Nitrided two stage screw and barrel (JU III 4500kN – JU III 5500kN)

- Chrome-plated variable pitch screw and Nitrided barrel (JU III 6500kN A/B – JU III 21000kN A/B)

- Alloy variable pitch screw and Nitrided barrel (JU III 6500kN C/D – JU III 18500kN C/D, JU III 21000kN C)

- Bi-metal high mixing screw and Nitrided barrel (JU III 2100kN D, JU III 24000kN – JU III 55000kN)

- Water cooling control system for hopper cooling ring

- Suck back before dose

- Cooling before dose

- Barrel heating cotrol loop(K type,J type all applicable)

- Barrel heating preservation function

- Barrel temperature cycle start function

- Barrel temperature synchronous heating function

- Plasticizing cold start prevention function

- Barrel temperature is controlled by manual mode

- Injection curve monitoring function, memory function

- 6-stage injection unit control(1-6 stage can be set)

- 5-stage hold pressure control(1-5 stage can be set)

- 5-stage dose control(1-5 stage can be set)

- 5-stage back pressure control(1-5 stage can be set)

- V/P switching (positon, time, pressure OPT)

- Three nozzel back modes (after dose, before mold opening and after injection)

- Back pressure proportional controlled

- Automatic material cleaning function

- Injection not fully plasticized material fuction

- Secondary dose function

- Hydraulic servo control system

- Mold open/close proportional control

- Temperature monitoring, oil temperature upper and lower limit alarm

- Superfine by-pass independent oil filter

- Detachable oil fiter

- Tank level gauge

- 2 sets core pullers (JU III 4500kN – JU III 14000kN)

- 3 sets core pullers (JU III 16000kN – JU III 28000kN)

- 4 sets core pullers (JU III 33000kN – JU III 55000kN)

- Check valve for core superposition (JU III 7500kN – JU III 55000kN)

- Core position signal 16 - pin industrial socket

- External oil cooler (JU III 7500kN – JU III 55000kN)

- Mold cooling water connector (fixed platen 8 pcs) (JU III 4500kN – JU III 6500kN)

- Mold cooling water connector (fixed platen 8 pcs,moving platen 8 pcs) (JU III 7500kN – JU III 14000kN)

- Mold cooling water connector (fixed platen 10 pcs,moving platen 10 pcs) (JU III 16000kN – JU III 24000kN)

- Mold cooling water connector (fixed platen 12 pcs,moving platen 12 pcs) (JU III 28000kN – JU III 33000kN)

- Mold cooling water connector (fixed platen 16 pcs,moving platen 16 pcs) (JU III 40000kN – JU III 55000kN)

- Thin-oil central lubrication system for mold clamping unit

- Electrical interface of the robot

- Reference protection fuction

- Temperature control with SSR

- Temperature warning device

- High precision transducer for mold open/close,injection,ejection,mold adjustment

- Ejector high precision displacement sensor

- High precision transducer for nozzel unit moving (JU III 13000kN – JU III 55000kN)

- KEBA controller with 15” touch screen panel

- Configure USB interface to achieve arbitrary large memory module

- Fault auto-analysis

- 3 sets of auxiliary power outlets for auxiliary equipment

- Emergency stop buttons

- Loop start button

- Hydraulic oil shortage alarm

- Clogging alarm of oil filter

- Fuse of heating leakage

- Built-in air auxiliary electrical interface

- Automatic power off when no action within the specified time

- Save mold parameters (maximum 200 items)

- Alarm record

- Operation modification record

- Multi-language switching (Chinese, German, English, Japanese, etc.)

- LCD screen brightness adjustment

- I/O Detection display function

- Molding cycle timing monitoring function

- Production management automatic monitoring function

- Moulding data table function

- Moulding quality discrimination function

- Quality exception alarm processing function

- Barrel heating monitoring function

- Exception handling selection function

- Equipped with serial communication interface

- Equipped with Ethernet interface