General purpose components

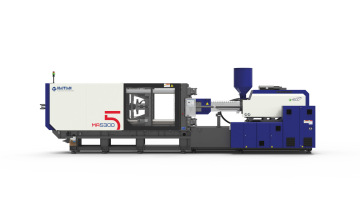

We will match all elements of the production workstations to the customer's expectations. Due to the wide range of industries, the individual requirements related to the selection of machines and peripherals will be tailored to each of them. Every manufacturing sector - automotive, household equipment, packaging, medical, construction - will be adequately supplied in terms of machines, robots and other peripherals.

01

Transport and Logistics

The selection of suitable machine for given manufacturing application is obviously the most important factor in production planning. Regardless of whether you need to produce parts with different dimensions or injection weights, you need to choose the right machine in terms of clamping force and maximum injection unit capacity. One of the most popular logistical items, large sized containers, will be the waste container with a capacity of 1100 litres. This type of part is produced on a Jupiter III 40000/106300 machine with an injection weight of 60 kg and in size of 1373 x 1073 x 1354 mm. Manufacturing such a container requires the use of HDPE + UV plastic, while the cycle time is 22 sec.

02

Furniture

Plastic elements used in the furniture industry are not only finishing accessories or various types of connectors. With the right design and optimal technology, such products include ready furniture pieces. One such example is the garden chair, produced on the Jenius III 9000/5200 machine from PP material with an injection weight of 2300 g. The entire cycle takes less than 50 sec.

03

Toys

One of the most popular products made from plastics are toys. The first example that comes to mind are toy blocks, larger or smaller in terms of injection weight and, of course, quantity per single production cycle. On the Zeres III 1200/300 machine we can produce a set of blocks in 20 seconds per cycle. The 8 cavity mould allows making blocks with a total weight of 52.88 g, where the dimensions of the workpiece are 31.65 x 31.65 x 23.7 mm, and the plastic used for this piece is ABS, which carries the load very well. The low post-production shrinkage allows confidence in maintaining the designed dimensions.