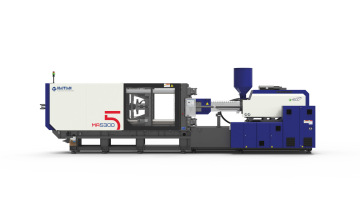

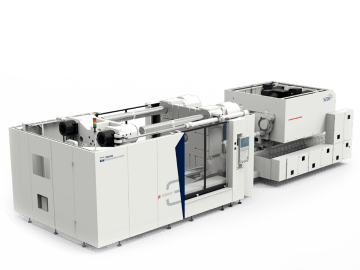

JENIUS III

The Zhafir Jenius (JE) Series is an innovative hybrid machine concept that combines electric and servo-hydraulic drive technology. Utilizing an innovative modular concept, the electric and hydraulic drives are combined in a highly efficient manner while maintaining their advantages. By combining the two technologies, the Haitian product portfolio, as well as the variety of applications, has been greatly enhanced in the Jenius Series machines.

Electric - two-platen hybrid

3 600 - 33 000 kN

Two-plate clamping system saves space

High precision, fast injection speed

Advanced solutions

Main benefits

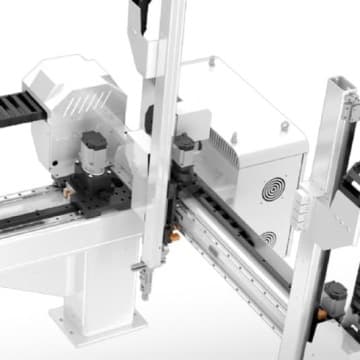

Space-saving two-plate design

Compact, two-platen design offers a smaller machine footprint combined with increased opening and ejector travel for a variety of applications

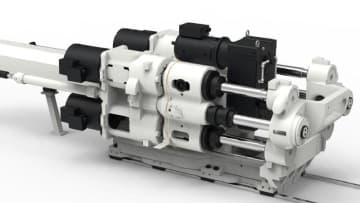

Advanced technology

Large injection units, design with 1, 2 and 4 spindles.

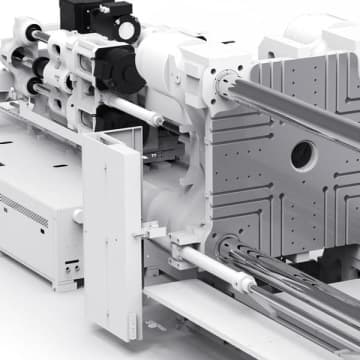

Swiveling injection unit

Swiveling injection unit for easy maintenance and fast plasticizing system change.

Standard technical specification of the JENIUS series

- Haitian standard T-slot + threaded hole mold platen

- The hole installion for robot (EU 18)

- Embedded positioning ring (fixed plate)

- Electrical and hydraulic double interlcok security

- Centralized thin oil lubrication system for clamping unit

- Electric automatic door (JE III 9000kN – JE III 33000kN)

- Crocodile mouth non-slip pedal (between tie bar and moving door) (JE III 9000kN – JE III 33000kN)

- Mould area safety pedal (JE III 9000kN – JE III 33000kN)

- Automatic mold height adjustment function

- 5-stage mold open/close,pressure & speed adjustable

- Fast mold opening device

- Low pressure mold protection function

- Spring mould fuction

- Mould clamping oil pressure sensor detection function

- Multi-stage proportional control of clamping force

- Safety and pressure limiting function of mold breaking pressure

- Mould clamping force pressure safe pressure limiting function

- Low clamping force holding function in the mode of mold adjustment when turn off the motor

- The clamping force can be decompressed automatically when the machine is off in manual and automatic mode

- Inverted double cylinder ejector mechanism (JE III 10800kN – JE III 33000kN)

- Three hydraulic ejector modes (vibration, hold, multiple times)

- Mechanical coupling for easier ejector connection

- Ejector back stroke adjustable function

- Program controllable of ejector(3 paragraphs)

- In-mold ejection function (in-mold cutting function)

- Eject back confirmation detection device

- Mould thimble protect electrical interface

- Delayed ejection function

- A/B ejection function (variable stroke ejection function)

- Automatic exhaust function of clamping cylinder

- Abrasion-resistant screw set, general version (open nozzle)

- Injection nozzle safety cover (with switch detection)

- 6-stage injection unit control(1-6 stage can be set)

- 4-stage hold pressure control(1-4 stage can be set)

- 3-stage dose control(1-3 stage can be set)

- 3-stage back pressure control(1-3 stage can be set)

- Screw suck back fuction after holding pressure or charge

- Screw suck back delay function

- Delay before injection

- Delay before charge

- Increased flow injection function

- V/P switch over methods by position/ time/ pressure combinations

- Injection speed responding mode adjustable

- Multi-stage control of injection pressure

- Hold speed setting

- Screw position setting (setting unit 0.01mm)

- Screw RPM setting

- Holding pressure time setting (setting unit 0.01s)

- Mold opening link function in charging

- Closed-loop control of barrel heating temperature (applicable for K type and J type)

- Barrel heating preservation function

- Barrel temperature optimize function

- Barrel temperature preheating function

- Barrel temperature synchronous heating function

- Resin retention prevention function

- Plasticizing cold start prevention function

- Auto purge

- Screw speed display

- Nozzle movement setting (switch detection, movement time)

- Three nozzel back modes

- High output nozzle contact device

- Nozzle centering alignment device

- Feeding zone temperature closed-loop control

- Swiveling injection unit

- Independent nozzle temperature control

- Heater quick plug

- Needle valve type nozzle drive (1 electric circuit spare)

- 50Kg iron hopper

- Bearing type transition slider (IU 1400 – IU3350)

- 15 inch color touch screen

- Save mold parameters (maximum 200 items)

- Alarm record

- Operation modification record

- 3 sets of USB interface

- Injection speed & pressure curve

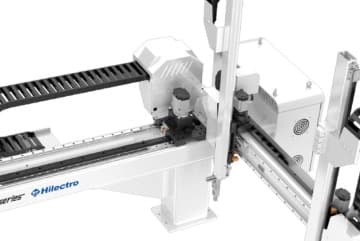

- Electrical interface of the robot (euro map 67)

- Multi-language available (Chinese, German, English, Japanese etc.)

- Metric/Imperial unit selectable

- I/O Detection display function

- USB printer interface

- Molding cycle timing monitoring function

- Production assistant device function

- Molding data record (display for 5000 cycles, save for 100,000 cycles)

- Moulding data table function

- Moulding quality discrimination function

- Quality exception alarm processing function

- Cycles counter

- The overall status list page

- Quick parameter setting function

- Equipment maintenance management function

- Barrel heating monitoring function

- Action cycle timing display function

- Three color alarm lamp (Red/yellow/green)

- Alarm buzzer

- Overfill prevention function (HPM pressure abnormality protection)

- Actual value display function

- Exception handling selection function

- Process parameter preset (start up)

- RFID login management

- Oil temperature and oil volume monitoring

- High-precision transducer

- Equipped with RS-232/422/485 communication interface

- Equipped with Ethernet interface

- Built-in gas-injection electrical interface